Convergence, like discrete pins in a lock tumbler aligning to allow the handle to turn. I have a mill, we were going to become grandparents, and the baby's other grand and great grandmothers planned to remove walnut trees from their properties. Three unrelated and isolated facts? Perhaps; sans an inclination to provide a tangible link between the little one and three generations of family.

This entry is a bit of a time machine. The cutting took place a year ago, after the wood was milled then air dried until ready. Here is the start of a journey from field to home.

|

| Black Walnut Slated for Removal |

So, get the saw and get to work. Funny, in the distance it looked absolutely puny. Up close, while not large, it was pretty good sized. Dada was right there lending a hand harvesting the tree with Gramps.

|

| Felled and Ready to Buck |

And by the time we got it all limbed and bucked, we had some tired helpers!

|

| Weary Woodsmen |

One of the key tools that make this whole venture workable is our log arch. There is no other way we could move these logs about with such ease. A toast to combining two simple machines; lever and wheel, into an effective package.

|

| Log Arch for Easy Move |

On the way home we pass by this lovely old frame building. Such a shame that it's being left to rot away....

|

| Log on the Road |

First of three logs delivered, two from Great Grandma and one from Grandma. The last of the batch will be project wood, the tree was damaged in an ice storm when small so had a large 'L' at about the 9' point in the trunk.

|

| Delivered! |

Here is number two; the upper log from the first tree ready to cut. The large limb ended up being the main feature of the project as you will see below.

|

| Up on the Mill |

Slab comes off and begins to reveal some beautiful wood beneath the rough exterior. Any chance there are parallels?

|

| Slab Comes Off |

After the boards are cut we put a second coat of sealant on the ends to reduce splitting.

|

| Seal the Ends |

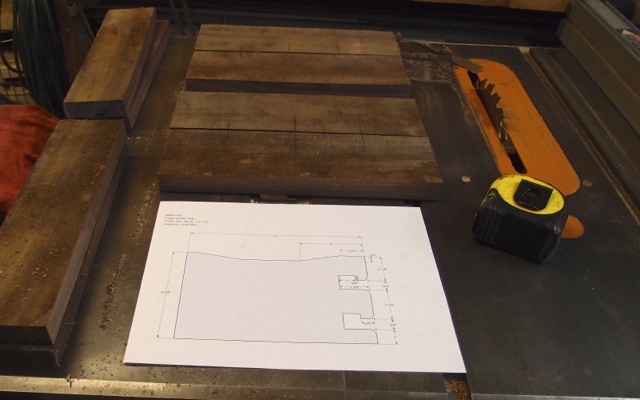

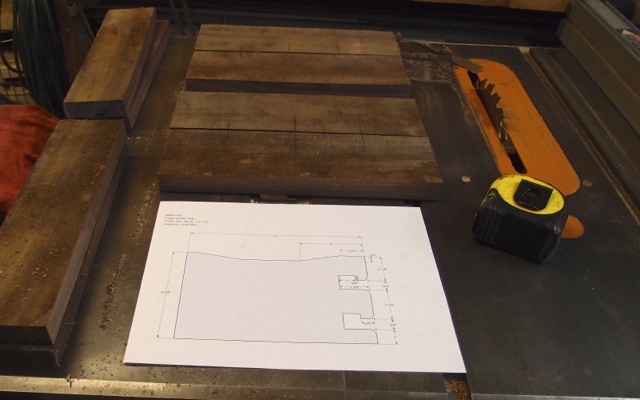

Fast forward one year and here are six boards in the shop as we try to figure out what to make and which ones to use. After some thought, and consultation with momma we narrowed it down to a high chair. More thoughts, sketches on paper, considering dimensions and we end up with a booster chair.

|

| Rough Walnut: Which to Use |

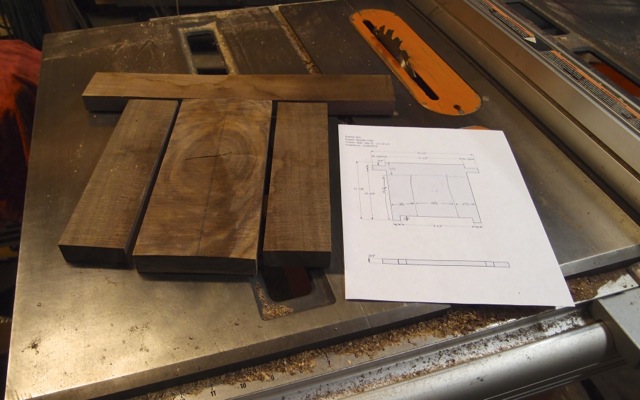

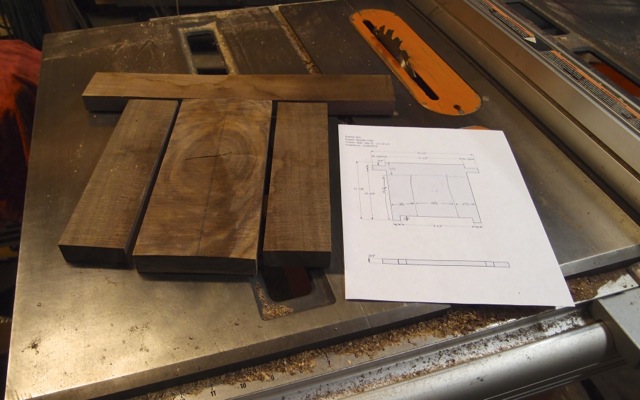

Some design work in SketchUp with help from Northern Lights Timber Frame Rubies, and viola a plan emerges.

After looking over the available lumber I decided to make the sides 'plain' and put one slice of knot in the center of the seat and another in the center of the back. The boards were just shy of being wide enough so they had to be joined. Probably worked better anyway, there was a good bit of cupping and other irregularities.

|

| Plan and Boards for Sides |

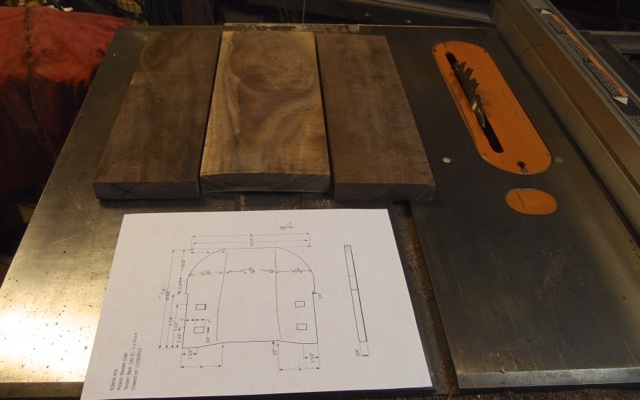

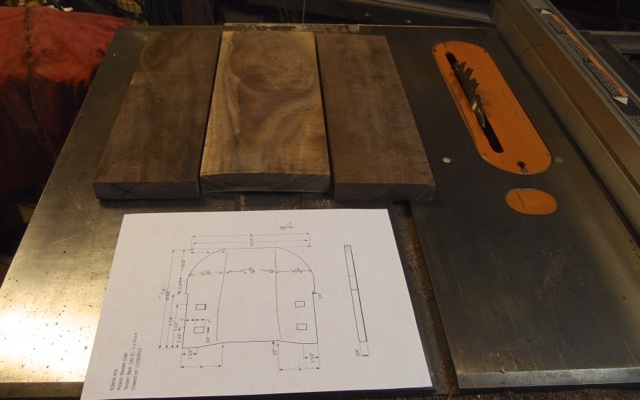

When rough it was hard to imagine the color and grain beneath the surface. Nothing quite as satisfying as uncovering that character with a sharp blade. I didn't realize the newer heartwood was going to be a shade of purple while the older center was a lovely chocolate with nice grain throughout.

|

| Side Glued and Planed |

After getting the boards to the right size it's time for a trip through the bandsaw to get the final shape.

|

| Final Shape of Sides |

Next is the seat. Embarrassed to say that I misread the plan (that I made up, and dimensioned) and cut each of the two sides an inch narrow.

|

| (Most of) The Seat |

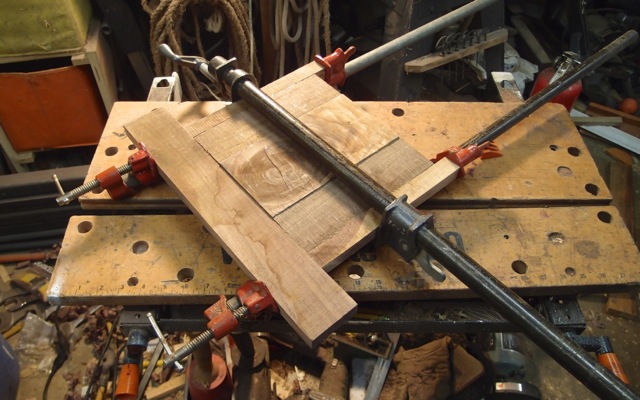

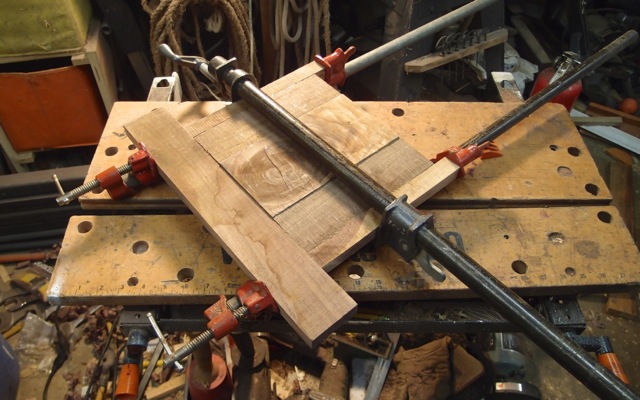

So, plan 'B', add some sapwood for effect. I didn't want to break into a new board so found a way to work in pieces from the scrap already cut. While satisfied with the way it turned out I learned some things that I'll try on the next project that may make it look even better.

|

| Seat Glue Up |

Here is the finished seat planed, cut, and rough sanded. With the crazy grain had a lot of trouble with pull out using the plane so resorted to a good bit of belt sander action.

|

| Seat Ready for Final Sanding |

Here is the back. Notice the significant cup on the center board due to stresses around the knot.

|

| Back Boards Ready to Glue |

All that flat stuff was biscuit joined to add a little strength.

|

| Joint Method: Biscuit |

Here it is after a rough sand and cut out.

|

| Back Ready for Final Sanding |

That's about time that Momma and Baby came to visit and see how things were coming along. I think it was probably the first time he had been in the garage, his eyes positively lit up. I could just imagine him thinking 'look at all the stuff I could get into here'.

|

| Making it Smooth as, Well, You Know |

The most fun was putting oil on the knots and watching the color and grain pop.

|

| Assembled with Oil FInish Going On |

Absolutely gorgeous.

|

| Close up of Grain |

Decided to put the outside of the tree outside of the chair. Seems 'right' for some reason.

|

| Back View |

Nice view of the back and seam mirroring each other. Pretty much done at this point. Will add a couple of coats of oil and rub it down, then put it to work!

|

| Finished Chair |